Are you still using cardboard as your solution to lining bins or separating parts during your production process? That material is absorbent so before you know it it is looking greasy and probably feeling very soft and unprotective.

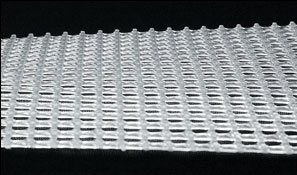

Industrial Netting has a solution – plastic netting! The open mesh construction allows air and fluids to flow freely. As an added bonus – the material is washable and reusable!

Many companies use this type of “green” netting for bin liners, tote liners, basket dividers and pallet liners. By allowing fluids to flow freely it is also ideally suited for applications that require dipping or washing.

Towing services and tow truck operators (as well as scrap metal dealers, auto crushers and recyclers, metal shredders, salvage yards and many others) are required to comply with Cargo Containment Regulation FMCSR 393.132 from the Federal Motor Carrier Safety Administration, which calls for the prevention of loose parts falling from damaged or wrecked automobiles during transport.

Towing services and tow truck operators (as well as scrap metal dealers, auto crushers and recyclers, metal shredders, salvage yards and many others) are required to comply with Cargo Containment Regulation FMCSR 393.132 from the Federal Motor Carrier Safety Administration, which calls for the prevention of loose parts falling from damaged or wrecked automobiles during transport.  The Extrusion Process

The Extrusion Process

Minneapolis, MN – Industrial Netting joined the

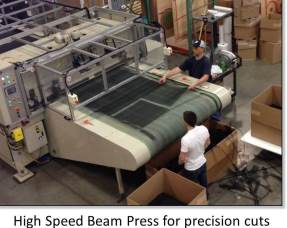

Minneapolis, MN – Industrial Netting joined the  Minneapolis, MN – Industrial Netting expanded its custom fabrication offering with the addition of a 110 ton Freeman Schwabe high speed

Minneapolis, MN – Industrial Netting expanded its custom fabrication offering with the addition of a 110 ton Freeman Schwabe high speed